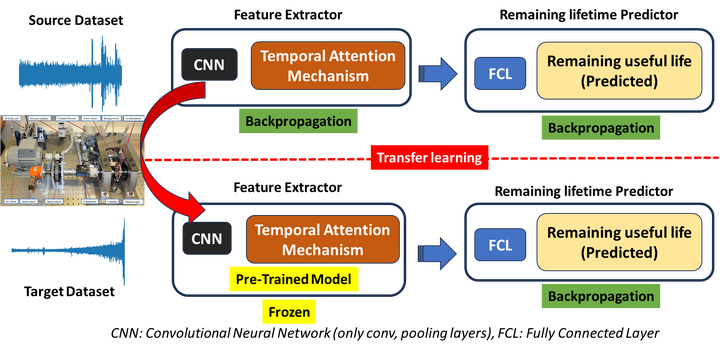

Fine-Tuned Based Transfer Learning with Temporal Attention and Physics-Informed Loss

Image credit:

Unsplash

Image credit:

Unsplash

Abstract

In the realm of industrial applications, ensuring the reliability of rotating machinery components, specifically bearings, is crucial to prevent unexpected downtime. Despite the benefits of integrating Deep Learning (DL) into Prognostics and Health Management (PHM) for improved Remaining Useful Life (RUL) prediction, challenges persist due to limited labeled data and generalizability issues. Transfer Learning (TL) offers a solution, yet fine-tuning with scarce target domain data poses a risk of Negative Transfer Learning (NTL). To mitigate this, we introduce a Temporal Attention Mechanism (TAM), dynamically weighing the importance of temporal channels and capturing local and global temporal dependencies. This ensures optimal focus on relevant temporal features during fine-tuning. Additionally, the conventional reliance on historical patterns in data loss functions for predicting degradation patterns introduces interpretability limitations. Thus, we propose a novel physics-informed loss function incorporating mechanical degradation factors, offering a comprehensive approach to accurate RUL predictions. Experimental results showcase the efficacy of TAM, achieving an average percentage reduction of approximately 50.93% to 90.67% in Mean Absolute Percentage Error (MAPE) compared to related works. The proposed Physics-Informed approach consistently outperforms traditional Mean Squared Error (MSE), demonstrating robustness and superior adaptability in diverse operating conditions.

Supplementary notes can be added here, including code and math.